Waterstops

Waterstops for concrete

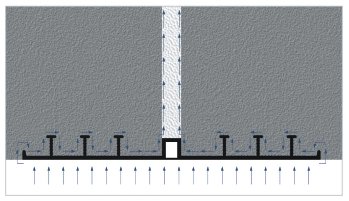

Hidroplasto sealing bands are used for sealing technical day joints during concreting as well as expansion joints in concrete and reinforced concrete structures. They are a passive barrier for penetrating water. The effectiveness of Hidroplasto insulating bands is facilitated by their shape and length of the arms and anchors with ribbed surfaces.

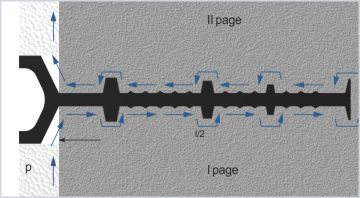

The route that must be traversed by the water to pass around the concreted band arms is greatly increased, and the direction in which it exerts pressure changes often. The achieved ‘labyrinth effect’ forces a water pressure drop, and in the end, puts a stop to subsequent penetration at the band-concrete joint.

Appropriately selected and concreted Besaplast insulating band is an effective barrier for groundwater and water under hydrostatic pressure. The broad range of insulating bands allows them to meet all challenges from constructional and architectural solutions and the conditions at the construction site, in terms of structure tightness and planned use.

Waterstops are the benchmark for the industry and exceed standard specifications. The versatility of PVC has made these waterstops popular with specifiers and engineers. Outstanding physical properties, excellent inherent elasticity and resistance to many waterborne chemicals has made it the most widely specified waterstop material.

PVC waterstops are available in several styles and sizes. Choosing the correct waterstop begins with determining whether the joint is moving or non-moving.

Typical Applications For PVC Waterstops Include:

Water and waste water treatment facilities

Dams, lock, canals, water reservoirs and aqueducts

Tunnels and culverts

Foundations

GENERAL INFORMATION

Product description

The perfection of the process of polymerisation of PVC on the industrial scale has allowed the development of a sealing band manufacture technology adapted to the needs of the construction industry. Knowledge of technical parameters of the material from which bands are manufactured, as well as the conditions of their introduction into the relevant structure, allows full usage of their advantages at a structure’s key points (day joints and expansion slits).

|

|

Besaplast sealing bands are an effective barrier for water flowing into the structure and site’s interior. The water intrusion paths, penetrating the concrete’s structure, seek out spots that are the least homogeneous and those characterised by interrupted continuity. That is why it’s important to care for a proper mix and the correct concreting work technology. Particular care has to be taken with respect to tightness of process technical and construction joints. Expansion joints are visible divisions in component continuity, where the ends of the divided structure parts are separated by a slit with a standard width of approx. 20 mm. Improper execution or complete omission of the water insulation, or complete negligence with respect to this insulation may hinder, and in the extreme case, prevent the use of the structure altogether.

Appropriately selected and concreted Besaplast bands are an effective barrier against pushing water.

The effectiveness of Besaplast insulating bands is facilitated by their shape and length of the arms and anchors with ribbed surfaces. The route that the water must pass to circumvent the concreted band’s arms is, thanks to this measure, markedly increased. The direction of water pressure influence changes often. The achieved ‘labyrinth effect’ forces a water pressure drop, and in the end, diminishing of its influence, and halt of further penetration at the intersection between band and concrete.

An important characteristic in terms of band choice are three parameters:

- the type of movements causing contraction, shortening or extension, which the protected structural components undergo as a result of actions of dynamic loads, temperature cycles, etc.- pressure on the band, due to pressurised water influences, surface water and underground water,

- type of joint to be sealed (expansion joints and joints preventing contractions, compression joints, day joints, etc.).

It is thus worth it to appropriately select the insulation, to limit the high costs of removal of damage or, in the extreme cases, of repairs required to the entire structure, should it be damaged by harmful influence of water and the aggressive substances dissolved in it.

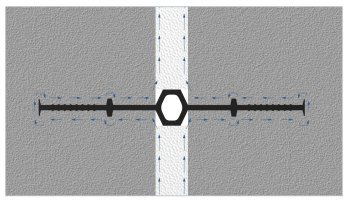

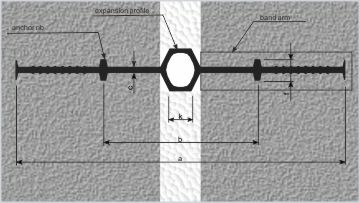

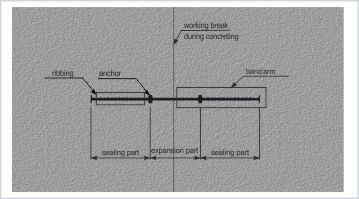

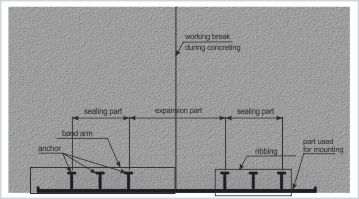

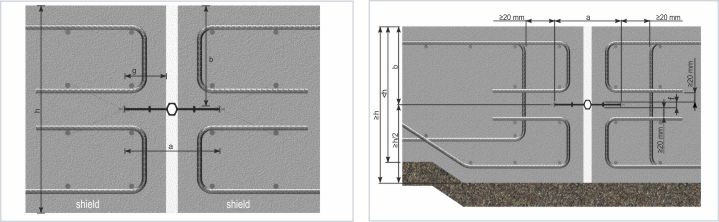

a – sealing band width

b – expansion part width

c – sealing band thickness in the expansion part

f – height of insulating anchor/insulating rib

k – expansion profile width

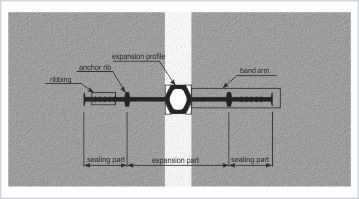

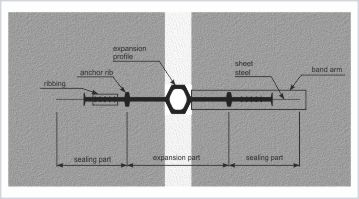

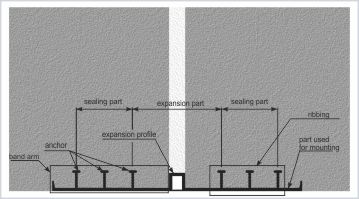

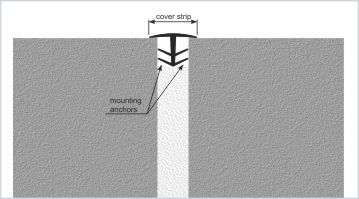

Sealing band structure

In order to unequivocally designate the vocabulary used, concerning the structure of bands, and to simplify studying of subsequent tabs of our website, here are visual presentations of the individual Besaplast insulating bands.

| Internal sealing band for expansion joints | Internal sealing band for expansion joints |

|

|

| External sealing band for expansion joints | Closing sealing band for expansion joints |

|

|

| Press-in sealing band for expansion joints | Internal sealing band for day joints |

|

|

External sealing band for day joints

The descriptions above allow clear determination of the selected product in your order. By indicating the name of the selected band, i. e. Internal sealing band for day joints, and the additional trade name of the material, i. e. Besaflex, along with the symbol, A 200, one obtains a unique name.

Subdivision of sealing bands

-

Day joint sealing bands

|

|

|

| internal | external | corner |

Thermoplastic material sealing bands, and elastomer sealing bands, as well as uncoated sheet steel, are the only systems covered by relevant German norms as basic solutions for component protection.

For the majority of structures, the use of internal sealing bands is recommended. External bands are used primarily under foundation slabs and in foundation walls, as well as in horizontal structural components.

External sealing bands must have the following minimum dimensions so that they might be used in spots susceptible to influence by pressurised water:

– width a = 240 mm with six insulating anchors, height f = 30 mm,

– width a = 320 mm with six insulating anchors, height f = 20 mm.

-

Expansion joint sealing bands

|

|

|

| internal | external | corner |

For expansion joints with a space between the divided components, bands should be used that have a compensation duct, which, through their geometry and the material they are made of, may transfer larger movements between structural components. Internal bands are used usually for structural component thickness values exceeding 200 mm.

In case of lower thickness values of the components to be insulated, external bands are used. In particular cases, special bands for mechanical installation are utilised. The selection of insulation of the expansion joint must take place after the determination of the scope of allowable shifts and relevant approximate water pressure values.

-

Closing sealing bands

|

|

| closing band type | press-in band type |

Closing sealing bands are used for closing expansion joints. As standard, they are used as additional protection for structures, in which external bands, and/(or) internal bands, are placed as well. The closing components, with two sealing anchors on one side, are used for closing of divisions susceptible to water not under hydrostatic pressure.

Closing bands with a minimum of four anchors are used as insulation from water under pressure equal to three metres of water column. The values given in diagrams on page 21, during selection of closing sealing bands for expansion slits with three anchors on one side, must be increased by an additional metre of water column against the presented values.

INDICATIONS CONCERNING STORAGE AND TRANSPORT

Storage

The bands should be stored on pallets, on a stable bottom surface, thermoplastic bands should be stored in a warehouse, if possible, and one day before the work, they need to be transferred to a heated room. While in storage, the free ends of the bands should be protected from damage. Thermoplastic material bands should be protected from direct influence of sunlight.

Transport

Bands should be transported on pallets, in a manner protecting them against hazardous atmospheric influences and protecting against mechanical damage. Possible damage to thermoplastic bands emerged during transport or storage is removed by spreading out the bands on an equal surface and thermal processing.

- the width of internal bands (a) may not exceed the width of the construction component, (c) bands must be chosen that are not too narrow (greater seal certainty), but also those that are not too wide (due to delamination). In addition, one needs to ensure appropriate installation depth – the covering layer (h) must be equal to or greater than the single-side anchoring depth (g).

If installation of internal sealing bands and external sealing bands is not possible, one should create a slab low point (rib in wall) to adapt the relevant component to the appropriate thickness. An exception in this case are Nitriflex internal bands with a width of 320 mm (types A and D). The DIN V 18971 norm allows concreting them into components with a width of 300 mm. This rule should be applied to components with a width of e = 300 mm.

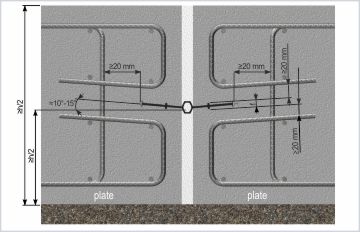

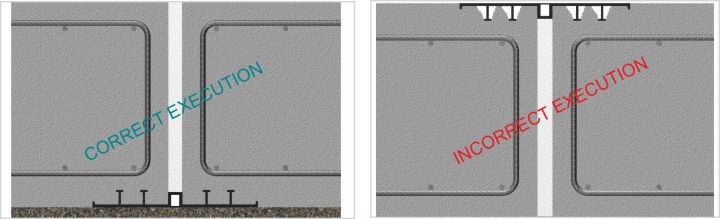

- the shape of reinforcement and location of internal bands in the foundation slabs and in the ceiling slabs must allow installation of bands in such a way so that its arms would be bent slightly to an angle of 10°-15°. Such a mode of installation is in place to eliminate the voids in the concrete from the sides of the ribs in the band underside.

- external bands may be arranged only on the side of action of water exerting pressure on it. Difficulties related to appropriate concreting of external sealing band anchors aimed downwards eliminate such a solution entirely. All cases of use of external bands as insulation for day joints and expansion joints in ceilings is wrong, and excludes the selection of such a solution already in the design stage.

- for internal sealing bands made of Besaflex and Nitriflex with a thickness of the expansion part (c) greater than the minimum required value as presented in the D series band table (page 44), one can use, for each additional millimetre of band, an allowable water pressure higher by 10%. Linear interpolation, however, may be conducted solely for bands with a width not exceeding the norm values indicated in the table by more than 5 mm.

- values in force for initial slit values wnom:

- external bands: 20 mm, with flexible part from 80 mm,

- internal bands: 20-30 mm, with flexible part from 90 mm.

Closed insulation system

It is important for the bands to form a closed insulation system, and for their free ends to be routed to at least 30 cm above the highest water level stemming from site observations. In case of basins and low points, the highest water level is the maximum projected fill level foreseen for a given structure.

If the building is divided by expansion joints, then all compensation hoses at the free ends of bands should be protected (closed) by a mass allowing adaptation to their shape, and the slits above should be protected using appropriate resources.

One should take particular care that:

- the expansion joints be straight,

- band widths along the same expansion slit do not change,

- external and internal bands are not joined together at one site.

If a passage is made between bands of different widths, the joint between them has to be made in the same way so as to maintain anchor continuity. Trimming bands, angles and changes of concreting levels of bands in day joints and expansion joints should, if possible, run at straight angles.

Minimum bend angle

When installing sealing bands, one often has to face the task of adapting their course to the altering form of the division to be protected. In order to avoid bends in sealing anchors, which could cause imprecise filling of the concrete mix around the band, one should adhere to the following bend angles:

- internal bands for day joints: r ≥ 150 mm,

- internal bands for expansion joints: r ≥ 250 mm,

- external bands: r ≥ 50 x f mm, where f – sealing anchor height,

- closing bands: r ≥ 30 x a mm, where a – band width.

The most obvious sealing band arrangement around a circular shape or circle section is the execution of components or structures with circular shapes. if the recommended bend angle radius cannot be adhered to, one should manufacture a pre-cast joining component, manufactured at a plant by a manufacturer or at the construction site by specialist installation teams.

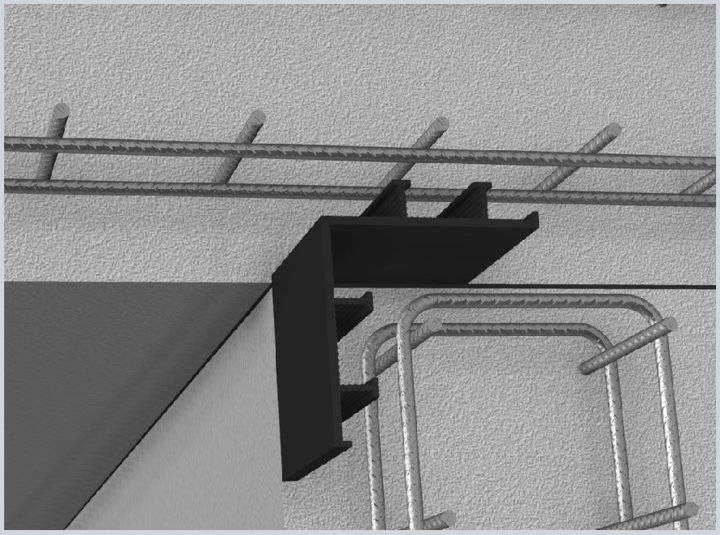

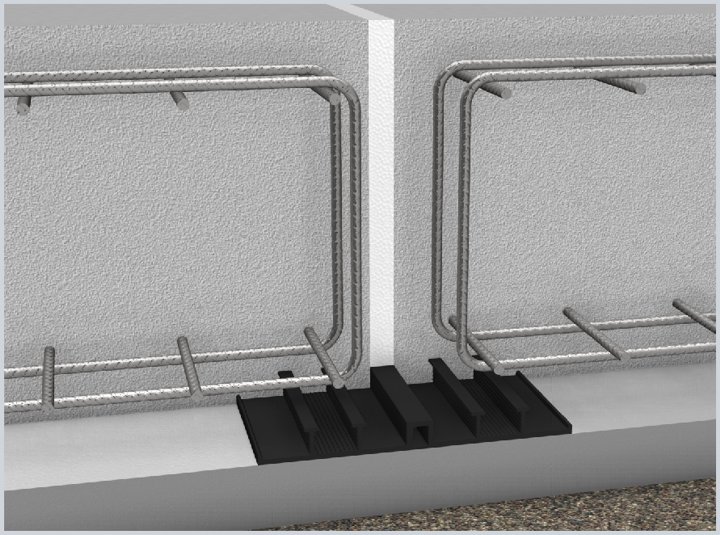

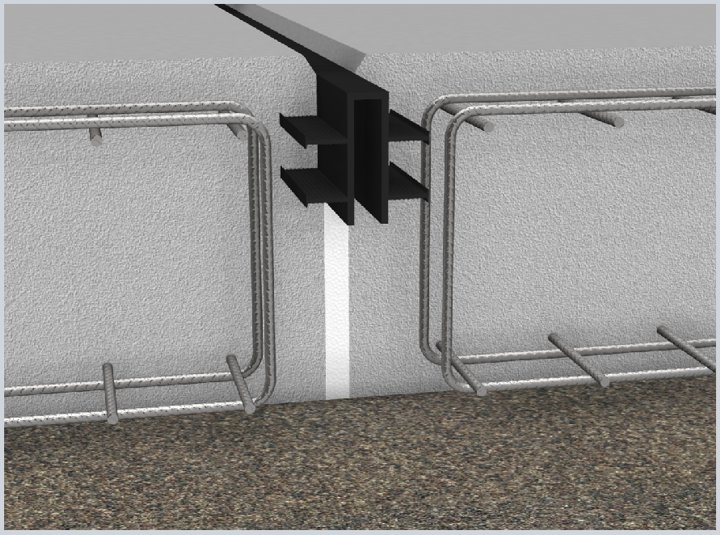

Band cover

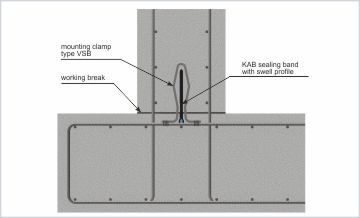

In order for sealing bands to properly fulfil their roles, they must be concreted appropriately. According to indications of standard DIN 18197 ‘Sealing of joints in concrete with waterstops’, between the sealing band and the steel reinforcement a distance of ≥ 20 mm must be maintained. The designed must, when beginning his work, reach a decision concerning the appropriate material for and type of band (internal, external, closing) together with appropriately designing the component reinforcement structure.

Only when designing a joint of the foundation slab with the wall, one may use internal bands without interfering in the reinforcement. in such a case, it is required that a threshold be made on the slab in order to embed the band. Such an addition should be made during concreting of the slab and not as an additional part. The use of Bestal steel mesh as stay-in-place formwork greatly simplifies this task.

|

|

| Use of an internal sealing band for day joints | Use of Bestal day joint bands |

|

|

| Use of type Kab sealing bands with swell profiles |

Allowable deformation vector

In order to select a sealing band for expansion joints, one has to know the shearing and cutting movements that will attempt to tear the installed band. When calculating the deformation, one should consider all deformations in directions x, y and z that may emerge during construction as well as during use. One may use the following formula to describe them:

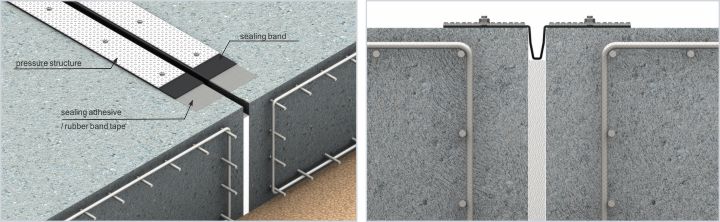

Selection of pressure and the determination of technical parameters of installation components for bands for mechanical mounting (using compression structures)

When faced with the dilemma of having to construct a tight solution of a joint between a newly-designed structure with an existing part, or with installation of bands in complex structures, where the band is supposed to provide protection at an intersection between a concrete structure with a building’s steel components, the use of mechanical assembly of bands using a compression system with a flange is both economical and appropriate in order to achieve tightness.

The selection of an appropriate sealing band, flat profiles, anchors, compression bolts and supplementary equipment should be preceded by a thorough design analysis. Having selected an appropriate band, one should determine the width and dimensions of the compression structure and the spacing and size of tension anchors. When using all the above named system components, one needs to provide a value for pressure of the band on the concrete that would be higher than the water pressure acting on the joints.

- for sealing bands for day joints, the same choice rules and design basics apply as for sealing bands for expansion joints. The band selection diagrams are not in force for bands installed mechanically.

The above information applies only to standard situations!!!

Sealing band selection diagrams

One should keep in mind that the option of using sealing bands is determined by the value of movements in the area of the division to be protected, the pressure exerted by the water acting on the band and the aggression level of the substances dissolved in the water. In order to appropriately select our products, the following diagrams show relations (scope of shift movements – water column pressure) for the individual sealing band types.

The scope of these structure shifts must be greater than or equal to the vector of allowable deformation (Vr) of the band, calculated using the formula:

| Besaflex type D | Nitriflex type D |

| Elastoflex type FM | Elastoflex type FMS |

| Besaflex type AD | Besaflex type FV |

| Nitriflex type DA | Nitriflex typeFA |

| Elastoflex type AM | Elastoflex type FAE |

INSTALLATION RULES

Preparing the bands for installation

Before the bands are mounted, they first have to be unrolled on a flat surface and checked thoroughly, whether they are not damaged or deformed in any way. It is not allowed to mount bands that have lost their proper shape. A particularly dangerous phenomenon are deformations of external band anchors, these can be caused by improper storage or transport.

On the day before installation, it is best to unfurl the band roll in a heated warehouse. This action can be replaced by short-term heating of the band in the flame of a burner. One has to note, however, not to keep the band for a longer time at one spot. The best result is achieved by several heating passes with the burner moving slowly along the band axis.

Band installation at the target mounting spot

When mounting bands, one has to make sure for the lengthwise axis of the band to be found (if possible) at equal distances with respect to the division to be sealed, and for the band to be installed in such a way so that it cannot move during concreting. In case of expansion bands, one should note that the compensation duct be found in the slit axis.

In case of expansion joints exceeding 20 mm, and joints with a tendency to exhibit compressive deformations (-Vx), in order to reduce the risk of damage to the internal band, one should create a so-called deformation chamber or cover the compensation duct with a closed cell elastomer material.

The arms of an internal band should be embedded in the concrete at a depth allowing one to hide the anchor ribs in the reinforcement cover foreseen by the designer (at least 30 mm), this should prevent it from being torn away from the component.

Bands should be fixed by way of installation grips and tie wire, to the rebar, at maximum spacings of 25 cm. Internal Elastoflex type sealing bands of types FS and FMS with sheet steel are installed by tie wire routed through openings in the sheet edges.

Installation of closing bands

Closing bands are installed with their arms downwards, on the formwork panel describing the course of the expansion slit. its arms, below the final closing anchor, should be affixed to the formwork with double-headed nails (with limiters) or with nails up to 40 mm in length (nailed down to a maximum of 1/3 of their length and bent away at an angle of approx. 45°).

Due to the risk of damage to the external bands at the construction site, it is advisable to use TF trapezoidal protective profiles, appropriately selected to suit the widths of the bands used. This profile, ensuring protection of the band against damage, also forms the edges of the concrete component. Such a solution protects the concrete component from mechanical damage, edge cracks or impacts.

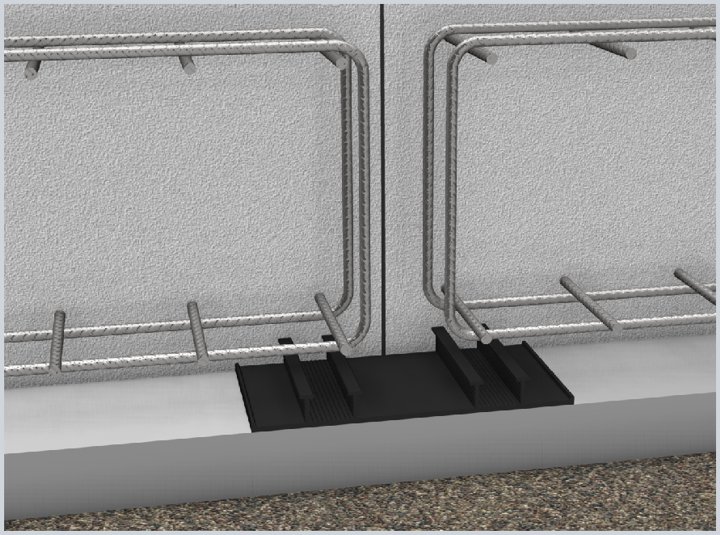

Installation of external bands

During the layout or unrolling of external bands at the construction site, execute formwork that shall not stand on the band’s anchors, on a layer of lean concrete or packed soil prepared for later execution of the foundation slab. The best solution for the execution of front formwork at spots of foreseen divisions is the use of steel lattices with trestles.

If the concreting technology or the pressure of the concrete mix should require the use of system formwork, they should be laid out outside of the band, with the remaining space levelled out with a fibreboard panel or veneer and edge battens. After the execution of a first concrete slab, the band should be secured against damage.

Directly before the execution of a subsequent slab segment, the free band arm should be cleaned of contaminants, i. e. cement bleed water, sand, sawdust, ice, aggregate and concrete remains. During cleaning, the condition and quality of the band should be checked again. Damaged sections of the band should be repaired or replaced. It is not allowed to burden band insulating anchors i. e. with lower rebar of the slab passing the day joint.

In such a case, during concreting, there exists a great probability of emergence of air bubbles or pockets close to the deformed anchors. When securing day joints and expansion joints of walls by using external seal bands, there emerges the problem of their affixing to formwork. If they are made of wood, the bands can be affixed to them with double-headed nails (with limiters) or with nails up to 40 mm in length (nailed down to a maximum of 1/3 of their length and bent away at an angle of approx. 45°).

The bands are pierced at the joining belt (band part between the final insulating anchor and its edge). One cannot pierce the sealing par and the expansion part of insulating bands.

In case of installation of external bands horizontally, they have to be reinforced additionally, or the top sealing anchor has to be installed in such a way so as to prevent it from tilting during concreting.

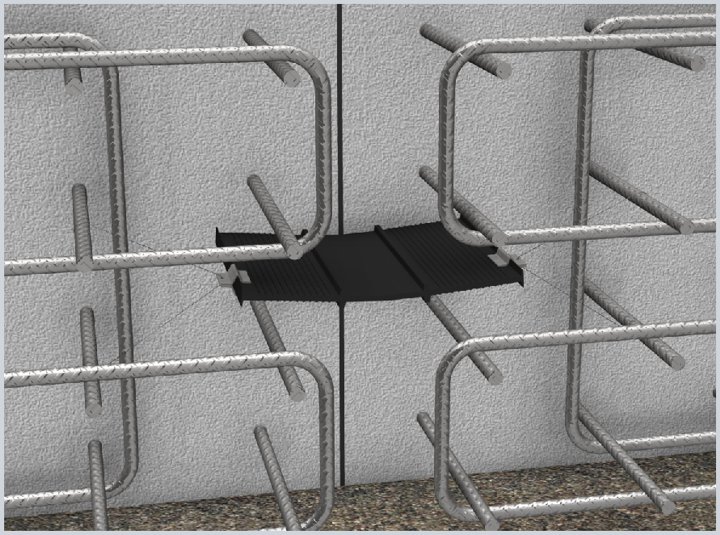

Installation of internal bands

The greatest difficulty during the installation of internal bands is the execution of divided head formwork. One has to ensure that the formwork is stable. Ready formwork lattices for day joints, with profiled pockets for the installation of sealing bands, provide great help.

For internal expansion joint bands, the formwork must be composed of two layers of fibreboard, installed in such a way so that the first layer is found at the height of the expansion duct, with the second layer closely covering the band’s arm.

In order to allow the internal band to close fully in the bottom slab or the ceiling, it has to be installed in a form resembling the shape of the letter V. The arm bands should be raised up to form an angle of 10°-15° with respect to the slab face. When installing internal bands at day joints and expansion divisions of walls, one should only ensure their stability by installing them with the use of installation grips and tire wire to rebar.

After concreting one band arm, the second, ‘free’ arm, should be secured against damage. Directly before the execution of a subsequent part, the free, un-concreted arm should be cleaned of debris and contaminants.

Installation of press-in masking bands

Press-in bands should be installed in previously executed and cleaned expansion divisions. In a temperature of at least 25 °C, in order to achieve greater susceptibility and flexibility of the bands, they can be heated before assembly with a burner or through storage at a heated location. Before installation, unfurl the profile at the slit, and, beginning on one end, press in the band using a batten or an edge profile, and hitting it additionally with a hammer.

Mechanical installation of sealing bands (with the use of pressure systems)

Before commencement of drilling and embedding of anchors and flat form profiles, determine the type and technical characteristics of all required components. Appropriate installation of bands using compression flanges is possible only for load bearing components on a flat and properly prepared surface.

The concrete surface for the compression structure must be water-tight, there may be no fractures or cracks or other kinds of contamination. If the surface does not correspond to these requirements, it is necessarily to repair it with putty or synthetic material-based mortar. By drilling openings for later introduction of studs, strive for the openings to be straight. One can use the compression flange as a matrix so as not to shift the anchor spacing.

The executed opening should be cleaned using a brush or pump. The best solution for introducing thrust studs is the use of adhesive chemical anchors. If such a solution is not recommended, use anchors with metal studs. In order to remove surface flaws close to the anchors and along the entire joint of the component with the band, apply joint sealing adhesive, i. e. Betofix.

After pressing out the adhesive from its container, spread it out at the joint using a trowel with a flat metal surface. Between the prepared surface and sealing band, place a rubber tape band sized 80 mm x 3 mm. The sealing band and the rubber tape band should be prepared for application over anchors by drilling at the required spots.

The necessary drilling of the bands should be done with a hand punch. After installation of the entire sealing system (adhesive mass + rubber tape band 80 x 3 mm + sealing band + compression flange) and after application of nuts to the anchors, tighten them with a torque wrench with the minimum calculated torque. The extrusion of a large volume of adhesive from under the band should be treated as a confirmation of appropriate pressure.

The action of tightening nuts (screws) should be additionally repeated at least three times every two weeks. In case of diminishing works, tighten the nuts (screws) directly before concreting. In case of mechanical installation at a section extending beyond 1,5 running metre, use compression flanges with a maximum length of 1,5 r. m., and even better – one running metre.

At the installation of a further flat profile, notice that the neighbouring joints do not overlap, with separation between them not exceeding 4 mm. Depending on the components to be insulated, it is possible to execute pressure systems on both sides, using the appropriate bands.

| Step 1. Base surface preparation. Priming and application of joint sealing adhesive. | Step 2. Drilling of holes and embedding of sealing band and flat profile. |

| Step 3. Installation of nuts and compression structure assembly, screw tightening. | Step 4. Concluded mechanical assembly. Subsequent pressure control. |

The remarks indicated in this catalogue are current information included in standard DIN 18197 in its current version.

Joining bands (welding)

Before commencement of actual, permanent joining of band ends, the band layout needs to be designed and the band needs to be trimmed. care should be taken to ensure a smooth band trim end without damage or frayed ends. It is best done with a swift single knife cut along a steel profile, adhering at the same time to an appropriate trim angle. When executing pre-cast components at a manufacturing plant, one can use more precise angular trimmers.

| Step 1. Band measuring | Step 2. Band trimmings into sections with an appropriate shape and size |

| Step 3. Melting band ends and joining them together. | Step 4. Processing the weld point or applying a masking tape band |

Besaflex, Nitriflex, Poliflex, TPE, PE and PP bands are joined together by welding.

As a result of thermal processing using appropriate tools, the contact surfaces remain both somewhat melted and joined together. Melting is conducted until emergence of surplus melt material on both sides of the trimming axe or knife. Then, the heated blade needs to be taken back. The bands need to be welded together from the centre out to the eds. The melting temperature of insulation bands, manufactured of appropriate materials, is between 160 °C and 220 °C.

In situations most often encountered at construction sites, only simple (butt) joints may be made. Other types of joints, which are more difficult (joining corners to make forms such as the T, L, X, cross profiles, passages of various bands) should be made at the manufacturer’s plant. An important factor influencing the seal of the entire system is the execution of joints by experienced personnel.

At the precasting plant, the quality of the executed joints should be tested with the use of a spark generator. This activity should be executed on a metal plate or panel. If a spark jumps the gap, from the generator through the executed weld joint, then this spot should be welded anew.

Elastoflex bands must be subjected to a more complicated joining process.

In this case, the joining takes place through curing, or in other words, through submitting rubber under pressure to heat. Such welds should be done in an autoclave or by using a curing device on a matrix approved for the relevant profile.

| Method |

||

| Welding |

Curing |

|

| applies to the following materials, | – Besaflex – Besaflex BS -Besaflex według normy zakładowej – Nitriflex – Polietylen |

– Elastoflex |

| material properties | Melting | Not melting |

| joint may be created using the following welding device | weld axe heater welding device |

curing device |

When joining sealing bands, the following devices should be used

|

|

|

| weld axe | Blow heater | Heating blade and matrix |

|

|

|

| Welder | Spark generator | Curing enclosure |

| Joining bands |

||||

| Besaflex |

Nitriflex |

Elastoflex |

Poliflex |

|

| Besaflex |

+ | + | – | – |

| Nitriflex |

+ | + | – | – |

| Elastoflex |

– | – | + | – |

| Poliflex |

– | – | – | + |

Concreting

Before the sealing bands are concreted, they should be cleaned of any possible contaminations. They must also be free of ice.

When pouring concrete, one should avoid single-side band pressure, the band may not tip or incline. During concreting works, it needs to be protected against mechanical damage. When the concrete mix is applied onto the band, even small damage spots may lead to the band tearing away. In case of components insulated with external bands, the concreting works should be conducted slowly, cautiously and from a low height, so that the anchors under load by concrete do not tip over and are fully concreted.

The concrete mix must be properly laid out and packed in the band’s vicinity. At the same time, make sure that the vibrating device end touches neither the band nor the band mounting components.

Formwork removal

In case of external bands, note that the band is not pulled out of too fresh concrete during formwork removal.

MATERIAL OVERVIEW

Besaflex

Besaflex sealing bands of elastic PVC are characterised by many excellent properties, providing savings over a structure’s lifetime. Flexible, soft PVC has been in use since the 1930s, and its properties are subject to constant research.

Besaflex sealing bands conform to all standard requirements, thanks to which they are broadly used in the construction industry.

They are resistant to acidic and alkali solutions, rotting and all other natural factors.

The broad selection of Besaflex products guarantees water-tightness of day joints and expansion divisions without interference in structural components (rebar).

Nitriflex

The material, from which Nitriflex bands are made of, is manufactured out of high-quality components, as corresponding to norm DIN 18541.

DIN 18541-compliant bands made of Nitriflex are characterised by maximum elongation at break, excellent resistance to chemicals and ageing as well as stable flexibility comparable to the flexibility of rubber.

The execution of diverse band joints is quick and cost-effective. Welding may be done using standard equipment, which is very simple thanks to the very good thermal conductivity of Nitriflex (for this purpose, one should not use heat welders with a power exceeding 300 W for band joining).

Nitriflex bands manufactured according to DIN 18541 may be shaped in various ways, thank to which they can be used for all kinds of structures, even to suit the most stringent requirements.

Elastoflex

Elastoflex seal bands are used of elastomer, or crossed multi-particle polymers with big openings (synthetic rubber), subjected to curing. Due to the crossing process being irreversible, special joining technologies must be used for their joining.

Elastoflex seal bands are perfect for use in structures with moving joints that are under threat of changing loads and low temperatures. Elastoflex insulation corresponds to norm DIN 7865.

Poliflex

Polyethylene bands were designed for sealing of pre-cast components.

This band type does not require the use of joining clamps, thus it can be used independently of the synthetic material insulation used earlier (i. e. mat, film, etc.) for executing joints in concrete structures.

Modified polyethylene bands are characterised by good weldability, resistance to aggressive chemicals and micro-organisms as well as high density. They do not lose their flexible properties in low temperatures.

Thermoplastic elastomer (TPE)

Joining and closing insulating bands made of TPE are characterised by greatest elongation at break, flexibility in low temperatures, as well as resistance to ageing and UV light.

Joining bands of this material is fast and cost-effective thanks to thermoplastic welding and using standard equipment (curing is not required).

BAND CHEMICAL PROPERTIES

Materials for use around potable water supplies

Besaflex sealing bands conform to all standard requirements, thanks to which they are broadly used

The company Besaplast manufactures also bands used in areas, where potable water appears. These are bands made of soft, coloured and flexible thermoplastic elastomer and polyethylene.

They are a fusion of good properties and workability, with additional adherence to Polish national and European provisions concerning synthetic materials and contact with potable water. They can be fully recycled.

Special characteristics:

- non-hygroscopic,

- mechanical properties in room temperature,

- good behaviour also after long-term ageing in water,

- natural colours,

- compliance with EU directive no. 2003/11/EC.

| Property |

Unit | Wymagania | ||||||||||

| Besaflex |

Nitriflex |

Besaflex (R-PVC) |

Besaflex wg BS |

Polietylen (PE) |

Polipropylen (PP) |

Elastoflex |

Thermoplastic elastomer (TPE) |

Test method according to |

||||

| N |

BV |

N |

BV |

|||||||||

| Shore hardness, type A hardness meter |

˚Sh | 75±5 | 67±5 | – | 80±10 | 90±5 | 62±5 | 62±5 | 62±5 | PN-EN ISO 868:2005 |

||

| Density | g/cm³ | 1,33±0,03 | 1,25±0,02 | 1,52±0,05 | 1,30±0,06 | – | 1,52±0,05 | – | 1,11±0,03 | PN-EN ISO 1183-2006 |

||

| Yield strength | MPa | ≥ 8 | ≥ 10 | ≥ 10 | ≥ 13 | ≥ 10 | ≥ 65 | ≥ 10 | ≥ 19,1 | PN-EN ISO 527-1:1998 (¹ PN-ISO 37:2007) |

||

| Elongation at break | % | ≥ 275 | ≥ 350 | ≥ 65 | ≥ 285 | ≥ 350 | ≥ 65 | ≥ 380 | ≥ 250 | PE-EN ISO 527-1:1998 (¹ PN-ISO 37:2007) |

||

| Shear strength | N/mm | ≥ 12 | ≥ 12 | – | – | ≥ 12 | – | ≥ 20 | ≥ 12 | PN- ISO 34-1:2007 |

||

Resistance of materials to selected chemical compounds

| Corrosive agent |

Concentration (%) |

Temp. (˚C) |

Material | ||

| Besaflex (soft PVC) |

Nitriflex |

Elastoflex |

|||

| acetone | any | 20 | – | +/- | +/- |

| acetone | 100 | 20 | +/- | +/- | not tested |

| ethyl alcohol | 10 | 20 | + | not tested | |

| 96 | 20 | – | – | not tested | |

| potassium-chromium alum (water solution) | any | 40 | + | + | not tested |

| alums (various kinds) | any | 40 | + | + | + |

| ammonia (water solution) | 15 | 40 | + | + | + |

| saturated | 40 | + | + | + | |

| aniline | 100 | 20 | – | – | not tested |

| ink | 30 | + | + | + | |

| silver nitrate | 10 | 60 | + | + | not tested |

| calcium nitrate | 20 | not tested | not tested | + | |

| benzene | 100 | 20 | – | +/- | – |

| petrol | 100 | 20 | – | + | +/- |

| borax (sodium borate) | not tested | not tested | + | ||

| borax (solution) | any | 40 | + | + | not tested |

| bromine (gaseous and liquid) | 20 | – | – | not tested | |

| buna (latex) | 20 | + | + | not tested | |

| butadiene | 100 | 20 | – | – | not tested |

| butanol | 100 | 20 | – | – | not tested |

| chlorine | any | 20 | – | – | – |

| methylene chloride | 100 | 20 | – | not tested | not tested |

| calcium chloride (water solution) | any | 60 | – | + | + |

| ferric chloride | any | 60 | + | + | + |

| chloromethyl | 100 | 20 | + | not tested | not tested |

| acetylene chlorohydrines (solution) | 20 | – | – | not tested | |

| acetylene tetrabromide | 100 | 20 | – | – | not tested |

| carbon tetrachloride | 100 | 20 | – | + | not tested |

| dextrin (water solution) | saturated | 60 | + | + | not tested |

| potassium dichromate (water solution) | saturated | 20 | + | + | not tested |

| carbon bisulphate | 100 | 20 | – | not tested | not tested |

| sulphur dioxide (gaseous) | any | 20 | +/- | not tested | not tested |

| ethyl ether | 100 | 40 | – | – | not tested |

| acetic ester | 100 | 20 | – | not tested | not tested |

| phenol | 20 | not tested | not tested | +/- | |

| phenol (water solution) | any | 20 | – | +/- | not tested |

| formaldehyde (water solution) | 30 | 20 | +/- | +/- | not tested |

| formalin | 20 | not tested | not tested | + | |

| freon 12 | 100 | 20 | +/- | +/- | not tested |

| glycerine | not tested | not tested | + | ||

| glycol | + | + | + | ||

| ethylene glycol | 100 | 40 | +/- | + | not tested |

| 60 | – | – | not tested | ||

| Corrosive agent | Concentration(%) |

Temp. (˚C) |

Material | ||

| Besaflex (soft PVC) |

Nitriflex |

Elastoflex |

|||

| glucose | saturated | 20 | + | + | + |

| carbolineum | 20 | 20 | – | not tested | not tested |

| fixing bath | 40 | + | + | not tested | |

| xylene | not tested | not tested | not tested | – | |

| nitric acid | 3 | 20 | +/- | + | + |

| 60 | + | not tested | +/- | ||

| 6 | 20 | + | + | + | |

| 40 | + | not tested | +/- | ||

| 15 | 20 | +/- | + | + | |

| 65 | 20 | +/- | not tested | +/- | |

| 40 | – | not tested | – | ||

| boric acid | any | 60 | + | + | not tested |

| hydrobromic acid | any | 40 | + | + | not tested |

| hydrochloric acid | any | 60 | + | + | + |

| chromic acid | 0,2-10 | 20 | + | + | not tested |

| citric acid | not tested | not tested | +/- | +/- | |

| phospohric acid (water solution) | any | 60 | + | + | + |

| tannic acid | not tested | not tested | not tested | + | |

| butyric acid (water solution) | 20 | 20 | +/- | + | not tested |

| concentrated | 20 | – | |||

| lactic acid | 20 | not tested | not tested | +/- | |

| formic acid | 10 | 20 | not tested | + | + |

| perchloric acid | any | 20 | +/- | + | not tested |

| acetic acid (anhydrous) | 100 | 20 | – | not tested | not tested |

| acetic acid (glacial) | 100 | 20 | – | +/- | not tested |

| acetic acid (wine vinegar) | 20 | +/- | + | +/- | |

| 40 | +/- | + | +/- | ||

| acetic acid (water solution) | 6 | 20 | + | + | + |

| 40 | +/- | + | +/- | ||

| 60 | +/- | +/- | +/- | ||

| sulphuric acid | 10 | 20 | +/- | + | +/- |

| 60 | 40 | +/- | +/- | not tested | |

| oxalic acid | not tested | not tested | +/- | ||

| carbonic acid | any | 40 | – | + | + |

| buttermilk | 20 | not tested | + | + | |

| methanol | 100 | 20 | – | not tested | not tested |

| urine | 20 | + | + | not tested | |

| urea | any | 60 | + | + | not tested |

| soapy water | saturated | 20 | + | + | + |

| potassium perchlorate (water solution) | saturated | 40 | + | + | not tested |

| hydrogen perchloride | do 30 | 20 | + | + | not tested |

| bromonaphthalene | 100 | 20 | – | not tested | not tested |

| fertiliser (liquid) | b | + | + | + | |

| nitroglycerin | 100 | 20 | – | not tested | not tested |

| nitro varnish (fixed nitrocellulose varnish) | fixed | 20 | – | not tested | not tested |

| butyl acetate | 100 | 20 | – | – | not tested |

| Corrosive agent | Concentration(%) |

Temp. (˚C) |

Material | ||

| Besaflex (soft PVC) |

Nitriflex |

Elastoflex |

|||

| ethyl acetate | 100 | 20 | – | – | not tested |

| lead acetate (water solution) | 20 | + | + | not tested | |

| oil, see: fats, diesel fuel, etc. | |||||

| linseed oil | not tested | not tested | not tested | +/- | |

| fuel oil | not tested | not tested | + | + | |

| diesel fuel, hydraulic oil | 100 | 40 | +/- | + | +/- |

| 100 | 60 | – | +/- | ||

| ricin oil | not tested | not tested | + | ||

| transformer oil | 100 | 40 | +/- | +/- | not tested |

| 60 | – | – | not tested | ||

| oleum | 10 | 20 | – | not tested | not tested |

| ozone | 20 | +/- | +/- | not tested | |

| paraffin | not tested | not tested | +/- | ||

| phosphoric pentoxide | 100 | 20 | + | + | not tested |

| ramasite | 20 | + | + | not tested | |

| copper sulphate (water solution) | any | 60 | + | + | not tested |

| calcium sulphate (water solution) | 20 | not tested | not tested | + | |

| hydrogen sulphide (gaseous) | 100 | 20 | – | not tested | not tested |

| liquid lubricant, spindle oil, etc. | 100 | 40 | +/- | +/- | +/- |

| Stauffer lubricant | 100 | 40 | +/- | + | not tested |

| tar | not tested | not tested | + | + | |

| aluminium salts | any | 40 | + | + | + |

| ammonia salts (water solution) | any | 60 | + | + | + |

| zinc salts | any | 60 | + | + | not tested |

| magnesium salts (water solution) | any | 60 | + | + | not tested |

| fertiliser salts (water solution) | any | 60 | + | + | not tested |

| nickel salts (water solution) | any | 60 | + | + | not tested |

| potassium salts | any | 60 | + | + | + |

| sodium salts, see: sodium chloride | |||||

| table salt (water solution) | any | 60 | + | + | + |

| engine exhaust containing carbon dioxide | any | 60 | + | + | + |

| engine exhaust containing hydrochloric acid | any | 60 | + | + | + |

| syrup / fruit syrup | not tested | + | + | ||

| liquid glass | + | + | + | ||

| sewage | 20 | + | + | + | |

| oxygen | any | 60 | + | + | + |

| fats (water suspension) | 20 | +/- | + | +/- | |

| plant and animal-based fats | 100 | 20 | – | + | +/- |

| toluene | 100 | 20 | – | +/- | + |

| trichloroethylene | 100 | 20 | – | not tested | not tested |

| hydrocarbons | saturated | 20 | – | + | not tested |

| red and white wine | + | + | + | ||

| Pe-Ce fibres (fixed) | 20 | – | not tested | not tested | |

| hydrogen sulphite (water solution) | any | 40 | + | + | not tested |

| 60 | +/- | + | not tested | ||

| Corrosive agent | Concentration (%) |

Temp. (˚C) |

Material | ||

| Besaflex (soft PVC) |

Nitriflex |

Elastoflex |

|||

| potassium hydroxide | 6 | 40 | + | + | + |

| 15 | 20 | +/- | + | + | |

| 30 | 20 | +/- | + | + | |

| concentrated | 20 | +/- | +/- | + | |

| concentrated | 40 | – | +/- | + | |

| sodium hydroxide (water solution) | 20 | not tested | not tested | +/- | |

| chlorine water | 20 | not tested | + | +/- | |

| rain water | + | + | + | ||

| Javel water (bleaching alkali compound) | 15 | 20 | +/- | + | – |

| lake water | + | + | + | ||

| glacier water | + | + | + | ||

| soft water | + | + | + | ||

| sea water | + | + | + | ||

| CO2-infused water | 100 | 20 | – | + | + |

| river water | + | + | + | ||

| condensed water | + | + | + | ||

| salty water | 40 | not tested | + | + | |

| calcium-poor water | + | + | + | ||

| water with high gypsum content | + | + | + | ||

| ferrocyanide | any | 60 | + | + | not tested |

| Corrosive agent |

Conc. (%) |

Temp. (˚C) |

T-type fitted carpet (PVC, HDPE) |

| butyl alcohol | 70 | 60 | + |

| ethyl alcohol | 70 | 60 | + |

| ammonia | concentrated | 60 | + |

| sodium chloride | concentrated | 60 | + |

| ferric chloride | concentrated | 60 | + |

| dextrose | concentrated | 60 | + |

| sodium dichromate | concentrated | 60 | + |

| sulphur dioxide (sulphuric water) | concentrated | 60 | + |

| glycerine | – | 60 | + |

| ethylene glycol | any | 60 | + |

| nitric acid | 10 | 60 | + |

| benzene sulphuric acid | 40 | 60 | + |

| benzoic acid | any | 60 | + |

| boric acid | concentrated | 60 | + |

| hydrochloric acid | 37 / 10 | 60 | + |

| chromic and phosphoric acid | concentrated | 60 | + |

| fluoric acid | 60 / 25 | 60 | + |

| phosphoric acid | 85 | 60 | + |

| tannic acid | concentrated | 60 | + |

| lactic acid | 10 | 60 | + |

| uric acid | any | 60 | + |

| acetic acid | 10 | 60 | + |

| sulphuric acid | 70 / 10 | 60 | + |

| carbonic acid | concentrated | 60 | + |

| methanol | 70 | 60 | + |

| hydrogen peroxide | 20 | 60 | + |

| nickel sulphate | concentrated | 60 | + |

| sodium sulphate | concentrated | 60 | + |

| hydrogen sulphide | concentrated | 60 | + |

| sodium thiosulphate salts | concentrated | 60 | + |

| sodium carbonate | concentrated | 60 | + |

| chlorine water | concentrated | 60 | + |

| magnesium hydroxide | concentrated | 60 | + |

| potassium hydroxide | 10 / 35 | 60 | + |

| sodium hydroxide | 10 / 35 | 60 | + |

+ = resistant

– = not resistant

+/- partially resistant

If you were looking for selected particular chemical compounds in the material resistance table, but have not found the relevant results confirming the actions of a particular corrosive agent, please contact the Technical Department of sales representatives. Betomax Polska may, at the customer’s request, conduct chemical resistance tests for bands from which sealing bands are made.

PRODUCTS

Day joint bands

The pauses during concreting are termed day joints, technical joints, temporary joints. Often due to technical and organisational conditions, the contractor is forced to conduct concreting works in a limited scope. The division of such works into phases is influenced by numerous factors, such as the speed of concrete mix binding, geometric shape of the executed site, limited formwork surface available to the contractor, machine effectiveness, ambient conditions, etc.

In general, one can say that day joints are joints that diminish with time, with the structure becoming a unified, monolithic system. These are, usually, weaker spots of components, and hence, it is recommended to place day joints in spots where external forces cancel each other out, or to design them ensuring appropriate cross-section load bearing capacity. A broad range of norms describes the rules of designing structures, where concreting works are spread out over a longer period of time.

Polish Standard PN-EN 1992 explains the term: ‘A complex component is a component made of concrete poured at the construction site and pre-cast concrete, joined by reinforcement bars or joined without reinforcement.’ This term closely relates to any divisions or pauses during concreting, where the pouring of concrete is delayed in time, but where it is not always related to the supply of ready components.

It is in turn necessary to lay out cross reinforcement through two components divided by a concreting interruption. At the same time, the German norm DIN 1045-1 describes such rebar as ‘stitching reinforcement’.

Standard ACI 318-08 of the American Concrete institute classifies joints as being either smooth surfaces or rough surfaces with purposefully created grooves. The shape of the executed day joint influences greatly the relevant component’s load bearing capacity as well as the tightness of such a joint. Executing a notched joint (bolt) for the purpose of more precise joining of structural components, can be done through the use of profiled day joint meshes (i. e. Streckmax mesh).

Beside day joints and technical joints, contraction joints are also important. These constitute targeted actions weakening the cross-section locally, aimed at creating cracks (fractures), contributing to the reduction of tensions exhibited by contractions.

Due to the need to ensure component tightness, one can differentiate between day joints that:

- do not require tightness,

- require tightness against the influence of ground water and other water acting on them, without pressure (i. e. external walls and foundation slabs, underground parking lots, ceiling roofs, etc.),

- must guarantee joint tightness for water under pressure (i. e. tanks, foundation containers, etc.).

Day joint sealing bands

| Besaflex | ||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| A100 | 100 | 40 | 3,0 | 10 | 25/40 | roll | 0,60 | SU-TU-BP-0-02042 |

| A120 | 120 | 45 | 3,0 | 10 | 25/40 | roll | 0,65 | SU-TU-BP-0-02043 |

| A150 | 150 | 45 | 3,0 | 10 | 25/40 | roll | 0,80 | SU-TU-BP-0-02044 |

| A200 | 200 | 70 | 3,0 | 15 | 25/20 | roll | 1,10 | SU-TU-BP-0-02047 |

| A240 | 240 | 80 | 3,5 | 15 | 25/20 | roll | 1,40 | SU-TU-BP-0-02048 |

| A320 | 320 | 110 | 4,5 | 15 | 25/16 | roll | 2,00 | SU-TU-BP-0-02054 |

| A500 | 500 | 150 | 6,0 | 20 | 25/2 | roll | 4,10 | SU-TU-BP-0-02060 |

Properties:

Besaflex type A sealing bands are characterised by high resistance to water ageing. The upper limit working temperature without load is approx. 80 °C, above this temperature, the band’s mechanical strength changes. Joining Besaflex bands is done by welding at temperatures of 120 °C-165 °C.1)2)

| Nitriflex | ||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| A190 | 190 | 70 | 3,5 | 15 | 25/20 | roll | 1,10 | SU-TU-BP-0-02045 |

| A240 | 240 | 80 | 4,0 | 15 | 25/20 | roll | 1,40 | SU-TU-BP-0-02049 |

| A320 | 320 | 110 | 5,0 | 15 | 25/16 | roll | 2,00 | SU-TU-BP-0-02055 |

| A500 | 500 | 120 | 6,5 | 20 | 25/2 | roll | 4,10 | SU-TU-BP-0-02062 |

Properties:

Nitriflex type A sealing bands are characterised by better chemical resistance and mechanical strength than Besaflex bands. They can be used for sealing of structures under threat of water at greater pressure values. Joining of Nitriflex sealing bands by welding allows for permanent and cost-effective execution of all kinds of joints of PVC bands.1)2)

| Polyflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| A200 | 190 | 70 | 3,05 | 15 | 25/20 | roll | 1,20 | SU-TU-BP-0-02136 |

| A240 | 240 | 90 | 3,5 | 15 | 25/20 | roll | 1,50 | SU-TU-BP-0-02137 |

| A320 | 320 | 110 | 4,5 | 15 | 25/16 | roll | 2,10 | SU-TU-BP-0-02138 |

| A500 | 500 | 120 | 6,0 | 20 | 25/2 | roll | 4,30 | SU-TU-BP-0-06301 |

Properties:

Polyflex sealing bands are characterised by good chemical resistance. They are particularly recommended for structures susceptible to low temperatures. Polyflex bands are joined by welding.

| Elastoflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

F 100100757,03225/6roll2,20SU-TU-BP-0-02232F 120120808,03225/5roll3,10SU-TU-BP-0-02233F 1501501008,03225/5roll3,50SU-TU-BP-0-02235F 2502501506,03225/5roll2,70SU-TU-BP-0-02052F 3003001006,03225/5roll3,10SU-TU-BP-0-02236F 3503501206,03225/5roll3,50SU-TU-BP-0-02237

|

Properties: |

High thermal resistance of type F Elastoflex bands are one of the most important criteria of their selection for insulating structures at locations, where they are in contact with hot bitumen compounds. Apart from that, they exhibit high tear resistance and relative elongation at break, which corresponds to being able to withstand liquid under pressure of approx. 25 m of water column.

| Nitriflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| ASI 200 D | 200 | 70 | 3,5 | 15 | 25/20 | roll | 1,70 | SU-TU-BP-0-02149 |

| ASI 240 D | 240 | 80 | 4,0 | 15 | 25/20 | roll | 2,00 | SU-TU-BP-0-02151 |

| ASI 320 D | 320 | 100 | 5,0 | 15 | 25/16 | roll | 2,80 | SU-TU-BP-0-02043 |

Properties:

Type ASI-D Nitriflex sealing bands have an internal steel reinforcement bar embedded in their cross-section. ø8 bars are distributed every 150 mm, providing better stability during installation at the joint between the foundation slab (foot) and foundation wall.1)2)

| Besaflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AS 100 | 100 | 50 | 3,0 | 10 | 25/40 | roll | 1,00 | SU-TU-BP-0-02139 |

| AS 120 | 120 | 60 | 3,0 | 10 | 25/40 | roll | 1,15 | SU-TU-BP-0-02140 |

| AS 150 | 150 | 60 | 3,0 | 10 | 25/40 | roll | 1,30 | SU-TU-BP-0-02141 |

| AS 200 | 200 | 70 | 3,5 | 15 | 25/20 | roll | 1,60 | SU-TU-BP-0-02142 |

| AS 240 | 240 | 80 | 3,5 | 15 | 25/20 | roll | 1,90 | SU-TU-BP-0-02144 |

| AS 320 | 320 | 100 | 4,5 | 15 | 25/16 | roll | 2,60 | SU-TU-BP-0-02146 |

Properties:

Besaflex type AS bands are characterised by equal properties to Besaflex type A bands. They are additionally bound by ø8 steel clamps every 150 mm. This provides better stability during installation at the joint between the foundation slab (foot) and foundation wall.1)2)

| Nitriflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AS 240 D | 240 | 80 | 4,0 | 15 | 25/20 | roll | 1,90 | SU-TU-BP-0-02145 |

| AS 320 D | 320 | 100 | 5,0 | 15 | 25/16 | roll | 2,60 | SU-TU-BP-0-02147 |

Properties:

Nitriflex type AS-D sealing bands have the same mechanical parameters as Nitriflex bands. They are additionally equipped with ø8 steel bar clamps distributed every 150 mm. They provide better stability at installation at the joint between the foundation slab (foot) and foundation wall.1)2)

| Nitriflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| A260 DBS | 260 | 120 | 9,0 | 26 | 25/4 | roll | 3,80 | SU-TU-BP-0-02053 |

| A320 DBS | 320 | 165 | 10,0 | 26 | 25/4 | roll | 4,30 | SU-TU-BP-0-02057 |

| A400 DBS | 400 | 190 | 11,0 | 30 | 25/3 | roll | 5,00 | SU-TU-BP-0-02059 |

Properties:

Nitriflex type A-DBS sealing bands have the same advantages of Nitriflex bands as the type A bands. However, the flexible part of these bands is thicker by approx. 6 mm as compared to their type A counterparts. Thanks to them being thicker, they are able to protect against water pressure higher by a factor of 1,5 than the pressure from the diagram on page 20.

| Besaflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| ASI 200 | 200 | 70 | 3,5 | 15 | 25/20 | roll | 1,70 | SU-TU-BP-0-02148 |

| ASI 240 | 240 | 80 | 3,5 | 15 | 25/20 | roll | 2,00 | SU-TU-BP-0-02150 |

| ASI 320 | 320 | 100 | 4,0 | 15 | 25/16 | roll | 2,80 | SU-TU-BP-0-02152 |

|

Properties: |

Besaflex type ASI sealing bands are charcterised by high resistance to ageing in water and conform to all standard solutions. Besaflex type ASI bands have an internal steel reinforcement bar embedded in their cross-section. ø8 bars are distributed every 150 mm, providing better stability during installation at the joint between the foundation slab (foot) and foundation wall.1)2)

| Elastoflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| FS 310 | 310 | 80 | 10 | 22 | 25/4 | roll | 4,20 | SU-TU-BP-0-06333 |

Properties:

Elastoflex type FS bands have all the advantages of Elastoflex bands, thanks to which they may be successfully used for providing tightness to tunnels and bridge structures. Their additional advantage is sheet steel embedded at arm ends, extending the water penetration route, and providing greater rigidity during installation.

Day joint sealing bands

| Besaflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AA200 | 200 | 80 | 3,5 | 20 | 4 | 25/5 | roll | 1,50 | SU-TU-BP-0-02067 |

| AA250 | 240 | 90 | 4,0 | 25 | 4 | 25/4 | roll | 2,00 | SU-TU-BP-0-02079 |

| AA250/35 | 240 | 90 | 4,5 | 35 | 4 | 25/4 | roll | 3,50 | SU-TU-BP-0-02080 |

| AA320 | 320 | 110 | 4,0 | 25 | 6 | 25/4 | roll | 2,70 | SU-TU-BP-0-02082 |

| AA320/35 | 320 | 110 | 4,5 | 35 | 6 | 25/4 | roll | 4,50 | SU-TU-BP-0-02095 |

| AA320/45 | 320 | 110 | 4,5 | 45 | 6 | 25/4 | roll | 4,90 | SU-TU-BP-0-02097 |

| AA500 | 500 | 120 | 4,0 | 25 | 8 | 25/2 | roll | 6,30 | SU-TU-BP-0-02102 |

| AA500/35 | 500 | 120 | 4,5 | 35 | 8 | 25/2 | roll | 6,70 | SU-TU-BP-0-02106 |

| AA625/35 | 625 | 300 | 5,5 | 35 | 10 | 25/1 | roll | 8,30 | SU-TU-BP-0-0210 |

| AA800 | 800 | 300 | 5,5 | 25 | 12 | 25/1 | roll | 8,30 | SU-TU-BP-0-02110 |

|

Properties: |

Besaflex type AA external sealing bands are the basic form of protection of day joints during concreting of foundation slabs and walls in buildings designed to be resistant to environmental influences classified as exposure classes X0, XC2, XC4, XS1, XS2, XS3, XF1, XF2, XF3, XF4, XA1, with structure type of S4 (per standard PN-EN 1992). Besaflex bands may be easily joined by welding.1)2)

| Nitriflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AA240/25 | 240 | 80 | 3,5 | 20 | 4 | 25/4 | roll | 3,20 | SU-TU-BP-0-02198 |

| AA240/35 | 240 | 90 | 4,0 | 25 | 4 | 25/4 | roll | 3,50 | SU-TU-BP-0-02077 |

| AA240/45 | 240 | 90 | 4,5 | 35 | 4 | 25/4 | roll | 3,90 | SU-TU-BP-0-02078 |

| AA320/25 | 320 | 90 | 4,5 | 45 | 4 | 25/4 | roll | 4,10 | SU-TU-BP-0-02093 |

| AA320/35 | 320 | 110 | 4,0 | 25 | 6 | 25/4 | roll | 4,50 | SU-TU-BP-0-02096 |

| AA320/45 | 320 | 110 | 4,5 | 35 | 6 | 25/4 | roll | 4,90 | SU-TU-BP-0-02098 |

| AA500/25 | 500 | 120 | 4,0 | 25 | 8 | 25/2 | roll | 5,40 | SU-TU-BP-0-06381 |

| AA500/35 | 500 | 120 | 4,5 | 35 | 8 | 25/2 | roll | 6,70 | SU-TU-BP-0-02107 |

|

Properties: |

Nitriflex type AA external sealing bands effectively protect day joints executed in foundation slabs and walls in structures classified as suitable for Besaflex bands against water influence. In addition, they may be used in structures under threat of chemically aggressive agents described as exposure classes XA2 and XA3, described in detail in standard EN 206-1. They are recommended for sealing day joints in concreted infrastructural objects, i. e. sewage treatment plants, petrol stations, and all kinds of manufacturing halls where process technical liquids are used.1)2)

| Elastoflex |

||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| A250 | 250 | 100 | 6,0 | 31 | 25/5 | roll | 3,50 | SU-TU-BP-0-02051 |

| A350 | 350 | 100 | 6,0 | 31 | 25/4 | roll | 4,80 | SU-TU-BP-0-02058 |

| A500 | 500 | 150 | 6,0 | 31 | 25/1 | roll | 6,60 | SU-TU-BP-0-06385 |

| A250-2 | 250 | 100 | 5,5 | 30 | 25/5 | roll | 3,10 | SU-TU-BP-0-08198 |

Properties:

Elastoflex type A external sealing bands are used for sealing day joints executed during concreting of foundation slabs and walls in road structures, tunnels, as well as foundation slabs and boxes for the purpose of servicing heavy industrial equipment. They are recommended everywhere where high shifts and dynamic forces burdening the structure are foreseen. Form profiles as well as al joining of Elastoflex bands should be executed by curing in an appropriate enclosure.

| Polyflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AAP240 | 240 | 90 | 4,0 | 25 | 4 | 25/6 | roll | 2,10 | SU-TU-BP-0-06386 |

| AAP320 | 320 | 110 | 4,0 | 25 | 6 | 25/6 | roll | 3,20 | SU-TU-BP-0-08212 |

Properties:

Polyflex type AAP external sealing bands are used for protection of day joint against water, in structures additionally protected by surface insulation made of PE film. They can be used in structures under threat of intense chemical aggression and low ambient temperature. Polyflex tapes are joined by welding at approx. 200 °C.

Corner day joint sealing bands

| Nitriflex |

|||||||||

| Symbol |

a1 [mm] |

a2 [mm] |

b1 [mm] |

b2 [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AA240 EA | 120 | 120 | 45 | 45 | 4 | 25/6 | roll | 2,00 | SU-TU-BP-0-02070 |

| AA240 EW | 120 | 120 | 45 | 45 | 4 | 25/6 | roll | 2,00 | SU-TU-BP-0-02072 |

| AA320 EA | 170 | 170 | 55 | 55 | 6 | 25/6 | roll | 2,00 | SU-TU-BP-0-02084 |

| AA320 EW | 170 | 170 | 55 | 55 | 6 | 25/6 | roll | 2,80 | SU-TU-BP-0-02090 |

| AA320 EI | 170 | 170 | 100 | 100 | 4 | 25/6 | roll | 2,80 | SU-TU-BP-0-02087 |

| AA500 EA | 250 | 250 | 85 | 85 | 8 | 25/4 | roll | 3,70 | SU-TU-BP-0-02099 |

| AA500 EW | 250 | 250 | 85 | 85 | 8 | 25/4 | roll | 3,70 | SU-TU-BP-0-02101 |

| AA500 EI | 250 | 250 | 85 | 85 | 8 | 25/4 | roll | 3,70 | SU-TU-BP-0-02100 |

| Besaflex BS |

|||||||||

| Symbol |

a1 [mm] |

a2 [mm] |

b1 [mm] |

b2 [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AA240 EA | 120 | 120 | 45 | 45 | 4 | 25/6 | roll | 2,10 | SU-TU-BP-0-06410 |

| AA240 EW | 120 | 120 | 45 | 45 | 4 | 25/6 | roll | 2,10 | SU-TU-BP-0-06411 |

Properties:The Nitriflex type AA external corner day joint sealing bands and the Besaflex BS type EC bands were designed to effectively protect structures at spots, where day joints were created at wall corners. Type EA, EI, and EW bands may be used in reinforced concrete components of varying thickness values.

Expansion joint sealing bands

Expansion joints are purposefully created divisions in building structures, designed to limit or remove tensions caused by temperature differences, concrete contraction, unequal setting and the effects of mining. In certain cases, expansion joints are made because the works are divided into phases and because of installation simplicity.

When designing the edge of an expansion joint, one has to take care of its shape and the form of reinforcement around it, so that they allow proper work of the expansion joint components in the relevant directions. One cannot lay out reinforcement bars through the expansion slit, and the edge of the slab should be reinforced along its length. Depending on their type, one can divide such joints into the following:

- structural (full) expansion joints – they separate a part of the building making up one complete whole in terms of statics, technology and foreseen structure use, or stem from its great size. It is recommended to separate by expansion joints parts of structures with different heights, and differing materially in terms of structural solutions, both with respect to statics as well as to materials. Expansion joints are usually made when a newly-designed structure is erected directly beside an existing one.

- thermal expansion joints – constructed so as to eliminate deformations of individual fragments of structures caused by varying thermal reactions and rheological properties of concrete. In order to ensure the freedom of deformation, the expansion slit should be provided with an appropriate width, allowing the structure to work as required, or otherwise execute components providing rigidity. When shaping the rebar arrangement to suit the thermal influences, one assumes that its components located in the soil are not susceptible to these effects.

- anti-vibration joints – in most cases associated with industrial construction, where they are supposed to protect a site or its individual constituent components against the influence of vibrations of foundations (dynamic and/or acoustic influences) and frame structures, on which machinery is located. Similar characteristics and the obligation of usage of building expansion joints are enforced through a structure’s location within an area of action of seismic waves caused by earthquakes or mining damage.

The Polish national attachment to standard PN-EN 1992-1-1 indicates maximum distances between expansion joints:

| Table no. NA.1 | |

| Structure type | Distance between expansion joints djont in metres |

| Structures subject to outside temperature variations a) non-reinforced walls b) reinforced walls c) reinforced concrete framework structures d) uninsulated roofs, cornices |

5 20 30 20 |

| Heated, multi-storey buildings a) internal walls and ceilings, concreted monolithically in one line as above – concreted in sections not exceeding 15 m in length, with spaces left over for later concreting c) internal pre-cast walls with external pre-cast walls d) as above – with external walls of aerated concrete e) as above – with light outside walls, lengthwise part providing rigidity in the central part of the building f) as above – with fixing walls in the end parts of the building g) pre-cast framework structures and monolithic structures with reinforcement in the central part of the building h) monolithic framework structures with walls providing rigidity in the end parts – as appropriate |

30 as in the case of internal pre-cast walls 50 40 70 50 as in the case of internal pre-cast walls as for a) or b)) |

| Heated single-storey reinforced concrete walls without walls providing rigidity or only in central part, with outside walls of low rigidity not experiencing cracking in case of deformations in their plane – depending on structure height h a) h≤5m b) 5 c) h ≥ 8 m |

60 10 + 10h 90 |

| Massive walls, if no special processes are used to reduce hardening heat and contractions depending on thickness a) b = 0,3 m ÷ 0,6 m b) 0,6 m < b ≤ 1,0 m c) 1,0 m < b ≤ 1,5 m d) 1,5m < b ≤ 2,0m |

|

Distances between expansion jointst indicated in table NA.1 do not apply to structures located in areas of mining activity, and do not apply to cases, when expansion joints are necessary for other reasons than effects of concrete contraction and temperature differences.

Internal day joint sealing bands

| Besaflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| D 120 | 120 | 70 | 3,0 | 10 | 10 | 25/10 | roll | 1,05 | SU-TU-BP-0-02164 |

| D 150 | 150 | 70 | 3,0 | 10 | 10 | 25/10 | roll | 1,15 | SU-TU-BP-0-02165 |

| D 200 | 200 | 90 | 3,5 | 10 | 10 | 25/8 | roll | 1,30 | SU-TU-BP-0-02167 |

| D 240 | 240 | 90 | 4,0 | 15 | 20 | 25/5 | roll | 1,65 | SU-TU-BP-0-02168 |

| D 320 | 320 | 110 | 5,0 | 15 | 20 | 25/4 | roll | 2,60 | SU-TU-BP-0-02174 |

| D 350 | 350 | 120 | 5,0 | 15 | 20 | 25/4 | roll | 4,40 | SU-TU-BP-0-02181 |

| D 500 | 500 | 150 | 6,0 | 20 | 20 | 25/2 | roll | 3,00 | SU-TU-BP-0-02185 |

Properties:

Besaflex type D sealing bands have all the characteristics appropriate for the material of which they are made. The selection of sealing bands for expansion joints is dependent upon the expected values presented in selection diagrams from page 20.1)2)

| Nitriflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| D 260 DBS | 260 | 120 | 9,0 | 28 | 20 | 25/4 | roll | 3,90 | SU-TU-BP-0-02173 |

| D 350 DBS | 350 | 170 | 11,0 | 30 | 20 | 25/4 | roll | 4,90 | SU-TU-BP-0-02183 |

| D 400 DBS | 400 | 190 | 11,0 | 32 | 20 | 25/2 | roll | 6,10 | SU-TU-BP-0-02184 |

Properties:

Nitriflex type D-DBS sealing bands possess all the advantages of Nitriflex type D bands. However, the flexible part of these bands is thicker by approx. 5 mm from the basic version. Thanks to this part being thicker, they are able to protect expansion joints against water pressure higher by a factor of 1,5 than the pressure from the diagram on page 20.1)2)

| Nitriflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| D 190 | 190 | 75 | 4,0 | 15 | 10 | 25/8 | roll | 1,40 | SU-TU-BP-0-02166 |

| D 240 | 240 | 95 | 4,5 | 15 | 20 | 25/5 | roll | 1,70 | SU-TU-BP-0-02169 |

| D 240/6 | 240 | 95 | 6,0 | 25 | 20 | 25/4 | roll | 3,00 | SU-TU-BP-0-02171 |

| D 240/9 | 240 | 95 | 9,0 | 25 | 20 | 25/4 | roll | 3,60 | SU-TU-BP-0-02172 |

| D 320 | 320 | 110 | 5,5 | 15 | 20 | 25/3 | roll | 2,70 | SU-TU-BP-0-02175 |

| D 320/6 | 320 | 110 | 6,0 | 25 | 20 | 25/3 | roll | 3,50 | SU-TU-BP-0-02177 |

| D 320/9 | 320 | 110 | 9,0 | 25 | 20 | 25/3 | roll | 4,10 | SU-TU-BP-0-02178 |

| D 350 | 350 | 120 | 6,0 | 15 | 20 | 25/3 | roll | 3,30 | SU-TU-BP-0-02182 |

| D 500 | 500 | 155 | 6,5 | 10 | 20 | 25/2 | roll | 4,60 | SU-TU-BP-0-02186 |

|

Properties: |

Nitriflex type D sealing bands have all the characteristics appropriate for the material of which they are made. The selection of sealing bands for expansion joints is dependent upon the expected values presented in selection diagrams from page 20. Thanks to the higher chemical resistance of the material, of which they are made, they can be installed in objects designed for exposure classes XA2 and XA3 according to standard EN 206-1 and for all standard solutions.1)2)

| Elastoflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| FM 200 | 200 | 110 | 7,0 | 32 | 20 | 25/5 | roll | 3,50 | SU-TU-BP-0-02238 |

| FM 250 | 250 | 125 | 8,0 | 32 | 20 | 25/5 | roll | 4,10 | SU-TU-BP-0-02239 |

| FM 300 | 300 | 175 | 8,0 | 32 | 20 | 25/5 | roll | 4,90 | SU-TU-BP-0-02241 |

| FM 350 | 350 | 180 | 12,0 | 38 | 20 | 25/5 | roll | 6,20 | SU-TU-BP-0-02243 |

| FM 400 | 400 | 210 | 12,0 | 38 | 20 | 25/4 | roll | 6,90 | SU-TU-BP-0-02245 |

| FM 500 | 500 | 300 | 13,0 | 38 | 20 | 25/2 | roll | 10,00 | SU-TU-BP-0-02246 |

| FM 250 – 2 | 250 | 125 | 6,0 | 26 | 20 | 25/5 | roll | 3,40 | SU-TU-BP-0-02240 |

| FM 300 – 2 | 300 | 175 | 6,0 | 28 | 20 | 25/5 | roll | 3,90 | SU-TU-BP-0-02242 |

| FM 350 – 2 | 350 | 350 | 6,0 | 30 | 20 | 25/5 | roll | 4,70 | SU-TU-BP-0-06356 |

Properties:

Elastoflex type FM bands may be used in structures susceptible to high movements of the separated components. They are an excellent solution for protection of expansion joints in road structures and press-equipped manufacturing halls, susceptible to high dynamic loads.

| Elastoflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| FMS 350 | 350 | 120 | 10,0 | 32 | 20 | 25/4 | roll | 5,20 | SU-TU-BP-0-02247 |

| FMS 400 | 400 | 170 | 11,0 | 32 | 20 | 25/4 | roll | 5,20 | SU-TU-BP-0-02248 |

| FMS 500 | 500 | 230 | 13,0 | 32 | 20 | 25/2 | roll | 8,00 | SU-TU-BP-0-02249 |

Properties:

Elastoflex type FMS bands should be used as Elastoflex type FM bands. The sheet steel embedded into the arm ends increase the water penetration route, and also provide increased rigidity during installation.

| Elastoflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| FMS 400 DS | 400 | 170 | 11,0 | 35 | 20 | 25/4 | roll | 6,20 | SU-TU-BP-0-08199 |

| FMS 500 DS | 500 | 230 | 13,0 | 35 | 20 | 25/2 | roll | 8,20 | SU-TU-BP-0-06369 |

Properties:

Elastoflex type FMS-DS sealing bands are foreseen for coverage of expansion slits in structures, where high positive and negative movements of expansion joints were designed. The executed expansion chamber allows greater band deformation close to the joint. In addition, at the ends of the arms of these bands, steel sealing bands are embedded. They possess all qualities applicable to Elastoflex type FMS bands.

| Elastoflex | |||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

k [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| FM 350 DS | 500 | 230 | 13,0 | 35 | 20 | 25/3 | roll | 4,70 | SU-TU-BP-0-02244 |

Properties:

Elastoflex type FM-DS sealing bands are foreseen for coverage of expansion slits in structures, where high positive and negative movements of expansion joints were designed. The executed expansion chamber allows greater band deformation close to the joint. They possess all qualities applicable to Elastoflex type FM bands.

| Besaflex BS | ||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| CC 150 | 150 | 116 | 5,0 | 20 | 25/5 | roll | 2,10 | SU-TU-BP-0-06302 |

| CC 200 | 200 | 87 | 5,0 | 20 | 25/5 | roll | 3,00 | SU-TU-BP-0-06303 |

| CC 250 | 250 | 116 | 6,0 | 24 | 25/5 | roll | 3,90 | SU-TU-BP-0-06304 |

| CC 300 | 300 | 166 | 7,0 | 24 | 25/4 | roll | 4,80 | SU-TU-BP-0-06305 |

Properties:

Besaflex BS type CC sealing bands, according to British standards, are characterised by better mechanical properties than their base material. However, in addition, they maintain all their advantages. Besaflex sealing bands are joined by welding. There are, in addition, no counterindications against joining Besaflex and Besaflex BS bands.

External day joint sealing bands

| Besaflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| AD 200 | 200 | 80 | 3,5 | 20 | 4 | 25/5 | roll | 1,70 | SU-TU-BP-0-02111 |

| AD 250 | 240 | 90 | 4,0 | 25 | 4 | 25/4 | roll | 2,20 | SU-TU-BP-0-02116 |

| AD 250/35 | 240 | 90 | 4,5 | 35 | 4 | 25/4 | roll | 3,70 | SU-TU-BP-0-02118 |

| AD 250/45 | 240 | 90 | 4,5 | 45 | 4 | 25/4 | roll | 4,10 | SU-TU-BP-0-02119 |

| AD 320 | 320 | 110 | 4,0 | 25 | 6 | 25/4 | roll | 2,90 | SU-TU-BP-0-02120 |

| AD 320/35 | 320 | 110 | 4,5 | 35 | 6 | 25/4 | roll | 4,70 | SU-TU-BP-0-02122 |

| AD 320/45 | 320 | 110 | 4,5 | 45 | 6 | 25/4 | roll | 5,10 | SU-TU-BP-0-02124 |

| AD 500 | 500 | 120 | 4,0 | 25 | 8 | 25/2 | roll | 5,60 | SU-TU-BP-0-02125 |

| AD 500/35 | 500 | 120 | 4,5 | 35 | 8 | 25/2 | roll | 6,90 | SU-TU-BP-0-02127 |

Properties:

Besaflex type AD external expansion joint sealing bands should be used to protect against water of expansion joints in buildings designed to be resistant to environmental influences classified as exposure classes X0, XC2, XC4, XS1, XS2, XS3, XF1, XF2, XF3, XF4, XA1, with structure type of S4 (per standard PN-EN 1992). Besaflex bands may be easily joined by welding.1)2)

| Nitriflex |

|||||||||

| Symbol |

a [mm] |

b [mm] |

c [mm] |

f [mm] |

Anchors | Package roll/pallete [mb/pcs.] |

Sales unit |

Weight [kg/mb] |

Art. no. |

| DA240/25 | 240 | 90 | 4,5 | 25 | 4 | 25/4 | roll | 2,20 | SU-TU-BP-0-02198 |

| DA240/35 | 240 | 90 | 5,0 | 35 | 4 | 25/4 | roll | 3,70 | SU-TU-BP-0-02200 |

| DA240/45 | 240 | 90 | 5,0 | 45 | 4 | 25/4 | roll | 4,10 | SU-TU-BP-0-02202 |

| DA320/25 | 320 | 110 | 4,5 | 25 | 6 | 25/4 | roll | 2,50 | SU-TU-BP-0-02211 |

| DA320/35 | 320 | 110 | 5,0 | 35 | 6 | 25/4 | roll | 4,70 | SU-TU-BP-0-02213 |

| DA320/45 | 320 | 110 | 5,0 | 45 | 6 | 25/4 | roll | 5,10 | SU-TU-BP-0-02215 |

| DA500/25 | 500 | 120 | 4,5 | 25 | 8 | 25/2 | roll | 5,60 | SU-TU-BP-0-06416 |

| DA500/35 | 500 | 120 | 5,0 | 35 | 8 | 25/2 | roll | 6,90 | SU-TU-BP-0-02224 |

|

Properties: |