Product description

Mutual support of beams and other components may be executed as dry type support, support on mortar, hard spacers or elastic spacers (meaning – elastomer spacers).

Direct support of component on component is usually used if light components are to be supported. One has to bear in mind that the surfaces in contact with each other are never perfectly smooth, and hence one has to account for the support and load bearing frames being unequal, and with certain spots experiencing elevated load values.

The deflection of the component being supported, and twist about the support component, lead to stress concentration on the edge.

Concentration of stress on the edge leads often to damage and cracking of edges. This can partially be counteracted by trimming the top support edge.

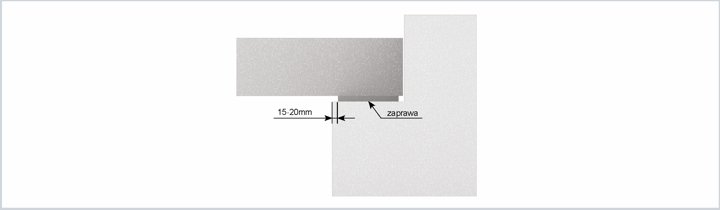

Support surface unevenness may be removed by applying a mortar layer having a thickness of 10-20 mm. Because this is an intractable support, there exists the possibility of cracking just as in case of direct support. These cracks can be counteracted by retracting the mortar layer from the edge of the supporting component by 15-20 mm. However, even this solution does not fulfil all requirements concerning the execution of proper structural component joints in modern construction.

A further method used to manufacture structural joints between construction components were, and sometimes still are, various types of felt. Felt allows the possibility of movement of the supported components, but just like with mortar, the joint does not give way, so structural failure can also arise.

Structure and properties of elastomer spacers

Elastic spacers, called elastomer spacers, are used more and more often as intermediate support components. They are a relatively new product, and have been used for 30 years now for supporting precast components and for making so-called articulated joints in monolithic components.

The task of elastomer spacers is the equalisation of contact joint stresses, assurance of free twisting of components on the support element and radical reduction of horizontal forces caused by: contractions, temperature influences and structure deformations.

As the name itself suggests, ‘elastomer spacers’ are made of elastomer. Elastomers are a group of natural and synthetic materials exhibiting great tendencies towards deformations and extensibility, while simultaneously maintaining their flexible properties across a broad temperature range.

The elastomer is a material with a specific particle structure. Its structure causes the material to lose tractability as the load increases, with material density and load bearing capacity increasing along. Elastomers maintain their ability to return to their initial form with little elastic deformation (i. e. they are almost flexible).

This is a very important characteristic, allowing these materials to be used in structures without the need for their replacement across the entire period of use of the structure.

As elastic spacers, in most cases synthetic rubber is used, and here we can name such rubber types as:

- Polychloroprene (CR) rubber

- Ethylene propylene diene monomer (EPDM) rubber

- Polyurethane (PU) rubber

- Natural rubber (NR)

- Polyurethane rubber

These types of rubber are not sensitive to temperature changes seen in the construction industry. Synthetic rubbers are subjected to ageing, which may lead to their hardness and elasticity modulus increasing. Natural rubber degrades under these conditions, with its stretching resistance decreasing. Such processes are, however, very slow – they occur over decades. Under the influence of ambient conditions (oxygen, ozone, UV light) only the surfaces of elastomers become damaged.

Experience collected up to this point shows that this is a very slow process, and the damage amounts to 1-2 mm after a few decades.

Elastomer spacers may be divided as follows by virtue of their field of use:

- spacers for ‘immobile’ joints – with limited ability to move

- spacers for moving joints

Spacers for immobile joints are spacers made of vulcanised rubber based on EPDM in a few basic variants, differing through their finishing surface or their cross section profile depending on the foreseen spacer work characteristics. Under load, the spacer deforms vertically.

The spacer thickness t is determined depending on the foreseen horizontal motions and turn angles α of joint components. Horizontal shifting on the support component occurs mainly under influence of contractions, temperature and beam deflection.

Forcing a horizontal shift is equal to the application of a horizontal force H. The knowledge of this force is necessary to correctly determine the dimensions of support components.

Under vertical load, the spacer has a tendency to expand sidewards. This phenomenon is counteracted by the surfaces of the supported and the supporting components. As a result of this, the spacer responds with contact tensions on the component surfaces, causing them to break close to the surface.

It must be stressed that the reason behind considering a shear force is only correct when the spacer surface (load bearing surface) and the load introduction surface (i. e. dispersion surface) have similar dimensions. If the spacer area is only a fraction of the dispersion surface, then the horizontal compression stresses occurring under the spacer will successfully remove the described shear forces.

Elastomer spacer types for moving joints

Slip elastomer spacers are used at spots, where ceiling slab movement or expansion or otherwise assurance of horizontal shifts of structural components exceeding 10 mm must be factored in. In such cases one may use slip elastomer spacers, in which the deformable and tractable elastomer part (the block or the core) is separated from one of the components by a teflon inlay.

They combine the ability to transfer great twists and the ability of providing greater shifts limited solely by dimensions of the slip panel. They are characterised by a low friction coefficient.

Types of slip elastomer spacers

- point slip elastomer spacers

- line slip elastomer spacers

It must be stressed that the reason behind considering a shear force is only correct when the spacer surface (load bearing surface) and the load introduction surface (i. e. dispersion surface) have similar dimensions. If the spacer area is only a fraction of the dispersion surface, then the horizontal compression stresses occurring under the spacer will successfully remove the described shear forces.

Elastomer spacer types for the execution of ‘immobile’ joints – with limited shifting ability.

Depending on the structure and work characteristic of the elastomer spacers, the following types can be named:

- flat outer surface elastomer spacers – non-reinforced, point spacers and line spacers – allow equal distribution of stress under them, and reduce the extension forces directly under the spacer;

- profiled elastomer spacers, in case of low compressive stresses, exhibit the ability to dampen sounds and vibrations;

- reinforced elastomer spacers, within which, in a layer of synthetic rubber, steel reinforcement plates are placed, reducing crosswise spacer deformations during compression.

plates are placed, reducing crosswise spacer deformations during compression.

The above indicated elastomer spacers are used for structures with small component spans, where the component shift values on the support elements are low, and where the shifts are compensated by horizontal deformations of the spacer itself (elastomer non-dilatational strain).

The estimated maximum relative shift for non-reinforced spacers should not exceed approx. 10 mm, and for reinforced spacers – approx. 30 mm.

Reinforced spacers should be protected against shifting, unless the minimum load is abided by. Sliding destroys the spacer.

If, however, we should be dealing with potentially intense relative shifts, then slip elastomer spacers are used, which are equipped with special slip surfaces.